sandwich panels

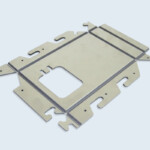

A sandwich panel is composed of two skins (or faces) stuck to a core. The assembly of these three elements form a unit of high rigidity and increased lightness compared to a homogeneous panel with the same mechanical properties.

- The skins can be metal sheets, plastic, laminate, wood or composite.

- The core is made either of aluminium, plastic, wood or cardboard honeycomb, or a solid plastic, composite or mineral core.

These panels are split into two large categories which we transform in our workshops.

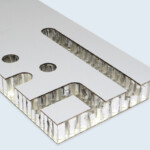

Honeycomb structure sandwich panels

Type: Alucore® – Compocel® – Larcore® – Nidaplast®

Skins: aluminium, wood, reinforced polyester …

Honeycomb core: aluminium, Nomex®, polypropylene…

Sectors: transport (rail, shipbuilding industry, aeronautic), machines, etc.

Honeycomb panels are sandwich panels with a honeycomb core that combines lightness and high mechanical performance: technical floors, ceilings, doors, partitions, facades, machine outer body, etc.

- Aluminium honeycomb: this all-aluminium panel has a high resistance to bending, as well as remarkable flatness, for a low weight.

- Polypropylene honeycomb: an economic and reliable solution ; the honeycomb core is covered in a non-woven fabric which allows the adhesion of the glue during the process of bonding the polyester skins to the aluminium

- Aramid honeycomb (Nomex®): non-metallic product, very light weight, resistant and an excellent electrical insulator; the honeycomb core is made of a meta-aramid fibre paper impregnated with phenolic resin.

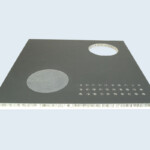

Solid core sandwich panels – composite panels

ype: Dibond® – Compocel® – Reynobond® – Alucobond® – Hylite®

Skin: aluminium, wood, plastic…

Core: plastic (compact or foam), mineral…

Sectors: display (display, point of sale), advertising panels, nautical/naval (furniture and partitions), industrial vehicles (cargo box), building/architecture (facade cladding), etc.

In this type, we find mainly aluminium composite panels (aluminium faces) which are renowned for their lightness, decorative and insulating qualities. They are also rigid, impact resistant and some have sound dampening qualities.

The sandwich panels with a foam core are excellent thermal insulators.

- DIBOND®– REYNOBOND® are sandwich panels consisting of two aluminium sheets with a polyethylene core. Lightweight, transformable in 3D, they are extremely stable and rigid. Interior and exterior applications, numerous colours and finishes possible. Specially designed for the display sector (displays, Point of Sale)

- ALUCOBOND® Plus and A2 are composite panels consisting of two sheets of aluminium with a mineral core. These panels are intended, distinctively, for architecture. Other external applications are possible.

- HYLITE®, the world’s thinnest composite panel (thickness 1.2mm and 2mm) has a special feature: its core can be used as a hinge.

- RENOZIST® is a true composite panel made of wood fibres and expanded polymers. It is lightweight, resistant and hydrophobic and rot-proof. It is also inexpensive.

Views: 343